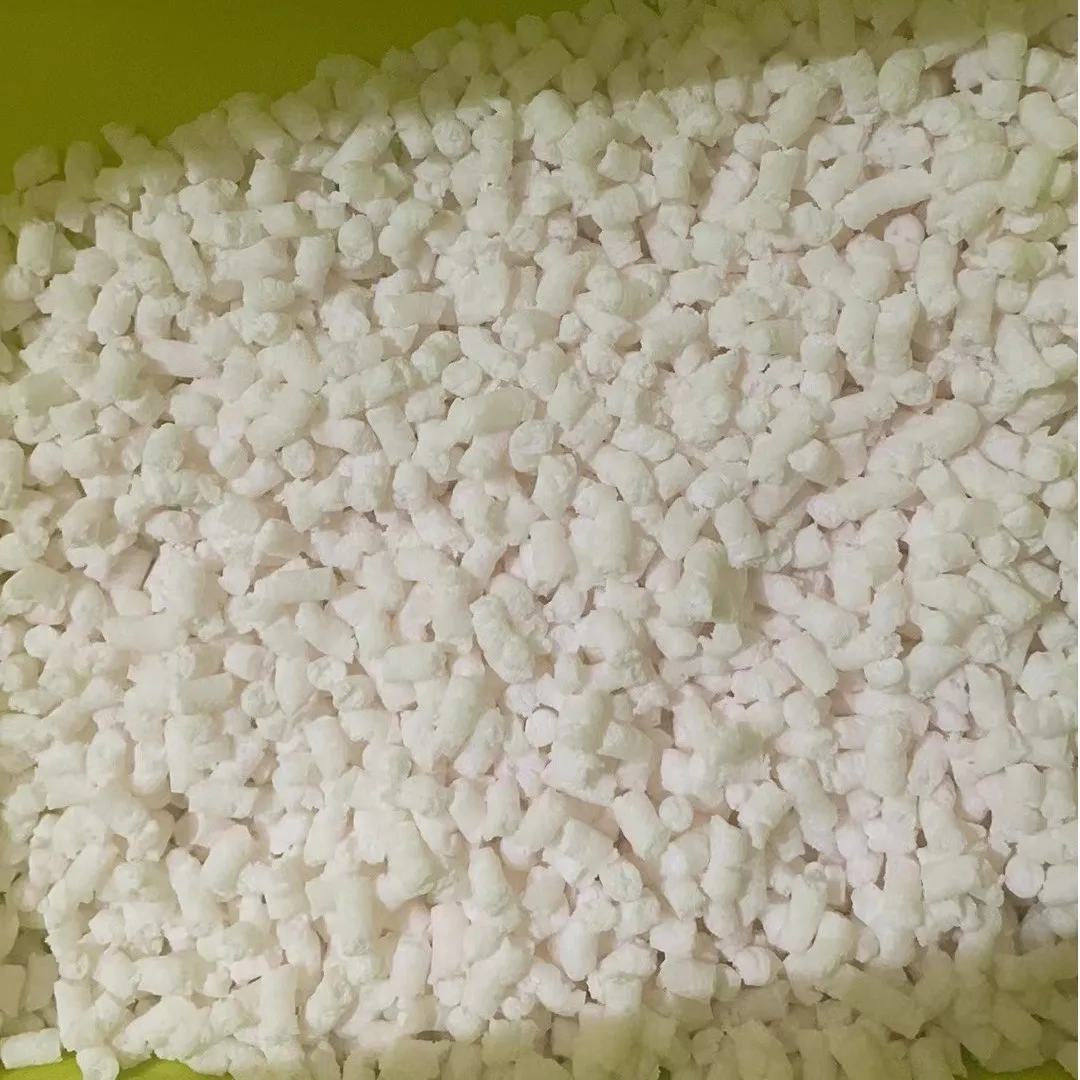

Styrene-Ethylene-Butylene-Styrene Copolymer

THERMOPLASTIC RESINS

Information

SEBS copolymer, or Styrene-Ethylene-Butylene-Styrene copolymer, is a type of thermoplastic elastomer that combines the properties of styrene and ethylene/butadiene. It is a hydrogenated version of SBS copolymer, which enhances its thermal stability, UV resistance, and chemical resistance. SEBS consists of hard polystyrene domains and soft ethylene/butylene segments, providing a unique combination of flexibility, elasticity, and durability.

SEBS copolymers are known for their excellent mechanical properties, low-temperature performance, and high transparency. They are widely used in various applications, including adhesives, sealants, coatings, and as modifiers for other polymers to improve their performance.

The versatility and enhanced properties of SEBS make it suitable for a range of industries, including automotive, consumer goods, and medical applications, where performance, safety, and durability are critical. Its ability to be processed like thermoplastics while exhibiting rubber-like characteristics makes SEBS a popular choice in many applications.