China Railway Shanhaiguan Bridge Group Co.,Ltd. (CRSBG)

Advance 2026

Information

China Railway Shanhaiguan Bridge Group Co., Ltd. (herein after referred to as CRSBG) was founded in 1894. It is China's earliest and most powerful railway turnouts and bridge steel structure manufacturing enterprise. It has manufactured more than 3,200 steel bridges and more than 400,000 sets of railway turnouts. It is known as China's "Cradle of Steel Bridges and Hometown of Turnouts."

Our position

We are located at the starting point of the Great Wall - Shanhaiguan, which is bordered by the Bohai Sea in the east, Yan Mountain in the north and Jieshi Mountain in the south. It is known as the "No. 1 Pass in the World" and is a place of important historical and cultural value in China.

Our Products and Services

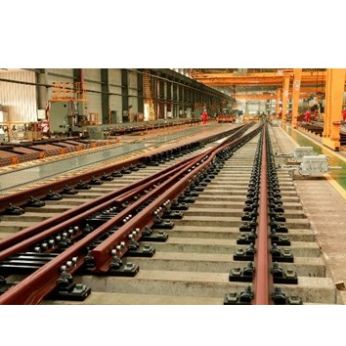

We specialize in the research and development, design, manufacturing, installation and after-sales maintenance of turnout products and their supporting parts. Our main products cover high-speed railways, heavy-load railways, urban rail transit, and factory-mine railway dedicated lines. We have participated in the six major speed-ups of China's railways. All of China's railway speed-up turnouts were first developed by our company. The 350 km/h series of turnout products we developed are widely used in China's high-speed railway network and have been successfully used in international projects such as the Jakarta-Bandung High-Speed Railway and the Hungary-Serbia Railway. The heavy-duty high-manganese steel series of frog products we developed have an average total weight of 35 million tons. We also produce large-span bridge steel structures and container gantry crane products, which are exported to more than 30 countries and regions. For 130 years, we have provided high-quality and high-performance products and won the trust and recognition of our customers.

Our capability

We have 6,000-ton presses, 52-meter CNC milling machines, 50-meter CNC drilling machines, advanced intelligent turnout automation production lines, pure steel frog production lines and turnout base plates intelligent production lines. We have core technical advantages such as high-speed and heavy-load turnout R&D and design, high-density high-manganese steel frogs, high-manganese steel frogs and rail welding, manganese steel casting hardening, rail hot forging and fine processing.

Our employees

We have more than 3,400 employees. Among them, there are 1,128 various management and professional technical experts, 35% of whom are technical R&D personnel, 14 professor-level senior engineers, 245 senior engineers, 249 engineers, and 2,252 professional and skilled personnel, providing a reliable talent guarantee for manufacturing high-quality products.

Our certifications

We have built a testing laboratory accredited by CNAS and certified by CMA, and have passed the qualification certifications of international authoritative organizations such as ISO9001, ISO14001, GB/T28001, EU TSI, UKAS, US Steel Structure Certification, German DVC, American Railway Association AAR, AWS and Canadian Welding CWB.

Our responsibility

We practice the social responsibility of green and sustainable development, optimize the ESG ecosystem, innovate green and low-carbon technologies, provide green products and services, build national green factories, and cultivate green and low-carbon industries. We create profits, return to shareholders, give back to employees, comply with business ethics, production safety, occupational health and other requirements, protect the legitimate rights and interests of workers, save resources, continue to empower society, and build a beautiful future of sustainable development.

Our slogan

Be a leading pioneer and making more perfection.